Quarter Sawn vs Flat Sawn Oak: The Ultimate Guide

Everything you need to know about the difference between quarter sawn and flat sawn oak wood

The difference between quarter-sawn oak wood and plain-sawn - also known as flat-sawn - oak wood is as simple as how the lumber is cut. How the lumber is cut, however, has a great deal to do with the look, feel, and durability of the resulting plank.

Quarter sawn oak became increasingly popular in the early 20th century as the wood of choice for arts and crafts style pieces.Today, with the wide use of plain sawn wood, quarter sawn oak can be used as an indicator for original or properly reproduced mission style furniture.

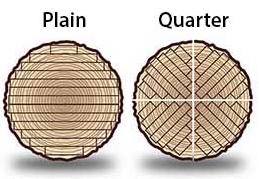

The Difference is in the Cut

Even with the same material, the cut matters a lot. Flat, or plain, sawn oak is the most common, efficient, and cost-effective way to cut a piece of lumber. Because of this, it is the most common method for cutting lumber. Generally, furniture made from plain-sawn lumber will be the least expensive option. Flat-sawn oak results from cutting the lumber in such a way that the growth rings of the tree intersect the face of the board at no more than a 30-degree angle, also known as tangential grain and it uses the least amount of lumber.

To produce quarter-sawn lumber means introducing a much more complex process. Quarter-sawn is a more time-consuming and waste-producing process - and therefore costly - for cutting lumber. The piece of lumber is rotated after each cut to ensure that the growth rings intersect the face of the board at or near a 90-degree angle. Quarter-sawn and rift-sawn lumber. are fairly similar.

Deciding Between Quarter Sawn and Flat Sawn Oak

Cutting a piece of oak with the plain sawn method will yield a plank that not only shows a significant flame - or cathedral-grain pattern on its face but also one more prone to cupping. Wood tends to cup in the direction opposite the bend of the growth rings. Due to the angle at which it is cut, flat-sawn oak can begin to warp over time as the growth rings are set at such a low angle to the face of the board.

The quarter-sawn method, on the other hand, creates oak that is much more structurally sound and resists cupping, twisting, warping, moisture penetration, and raised grain. One of the most sought-after features of quarter-sawn wood, particularly in white and red oak, is the flecks and the rays that appear on the face of the boards as a result of cutting along the growth rings. In oak wood especially, these flecks and rays can be quite dramatic and add a unique, striking quality to the wood.

The flecks and rays that abound in quarter-sawn oak wood are particularly prized and are essential features of mission-style antique and period piece furniture.

Review

While quarter-sawn oak is more expensive than plain-sawn, the value it provides in terms of structural integrity and beauty makes it the obvious choice for anyone looking for a quality piece. Because of the orientation of the growth rings during cutting, quarter-sawn oak wood is naturally resistant to cupping, penetration from moisture, and degradation by the elements. It also receives finishes and stains particularly well as compared to plain-sawn oak.

The superior nature of quarter-sawn oak has made it a favorite since the early 20th century in arts and crafts style pieces, and quarter-sawn oak, in particular, is the wood of choice for mission-style furniture, both old and new. Quarter-sawn white oak is another really popular option for furniture, cabinets, and flooring.

Quarter Sawn Oak Qualities and Benefits

- It is more stable and structurally sound than flat-sawn oak. Resists cupping, twisting, contracting, and expanding

- Quarter-sawn oak provides a much straighter wood grain on the face of the wood

- Due to its orientation at cutting, quarter-sawn oak boards often feature dramatic flecks and rays, which give each piece a unique and striking look